Thanks to its versatility and its ability to combine advanced simulation and structural optimization in a single environment, OptiStruct has revolutionized the way products are designed and validated. Its capability to handle multiphysics workflows, using a single model and a single solver, enables accurate simulations, reduces time-to-market, and drives efficient design optimization.

OptiStruct is successfully used in sectors ranging from automotive and aerospace to defense, electronics, civil, and architectural engineering.

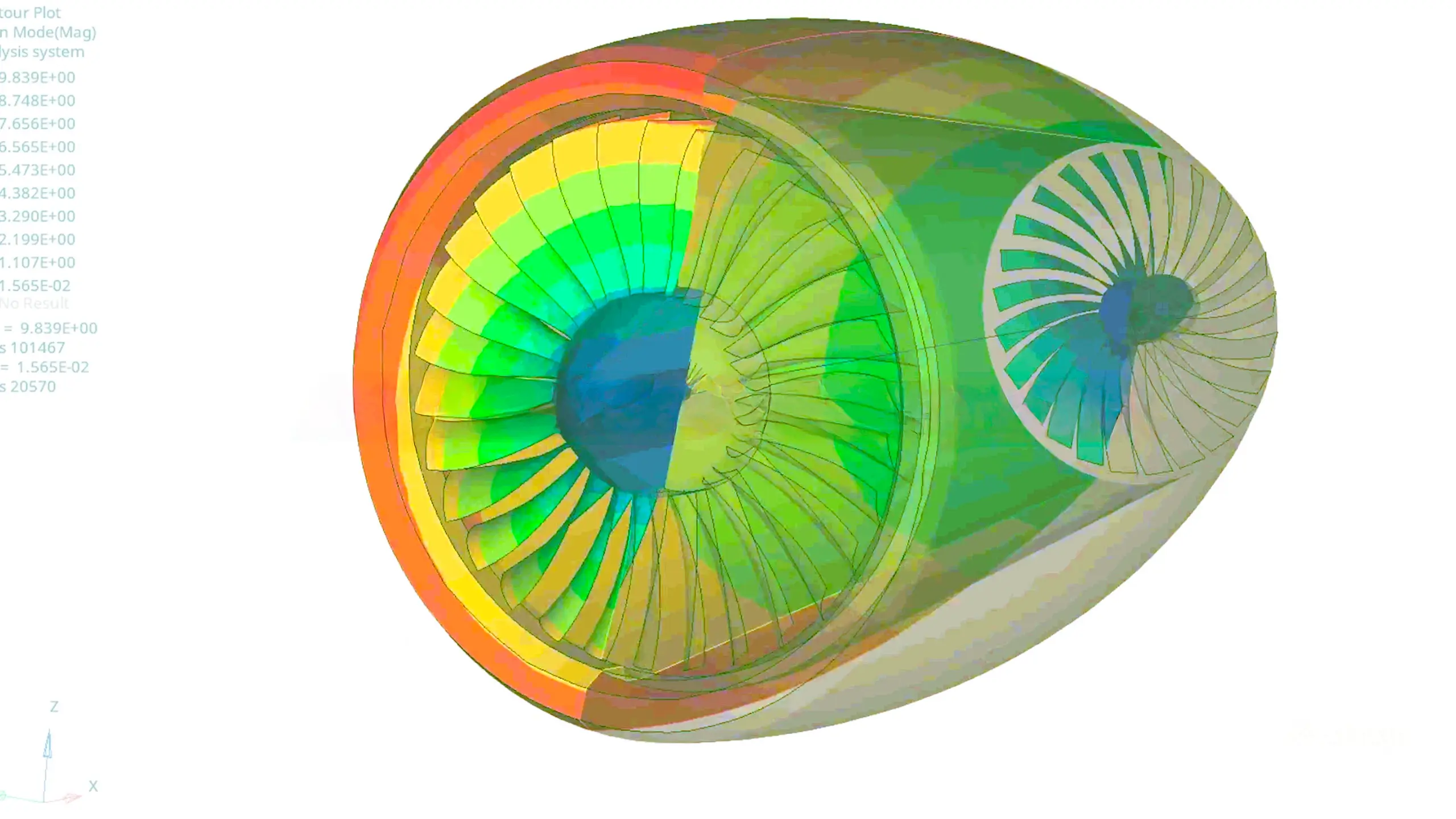

Vibro-Acoustic Analysis with Specialized Solvers

The integrated AMSES and FASTFR solvers enable efficient vibration and acoustic analysis, ideal for diagnosing issues at both the component and full-vehicle level. These capabilities support early-stage identification and resolution of NVH (Noise, Vibration, Harshness) problems during the design process.

Battery Thermal Management: A Multiphysics Challenge

As battery usage expands across industries, thermal management has become a critical factor in ensuring durability and safety.

OptiStruct integrates thermal, electrical, and structural simulations in a unified environment, allowing engineers to perform multiphysics analyses that optimize battery system behavior.

This approach enables in-depth evaluation of physical interactions, improving energy efficiency and reducing the risk of failure.

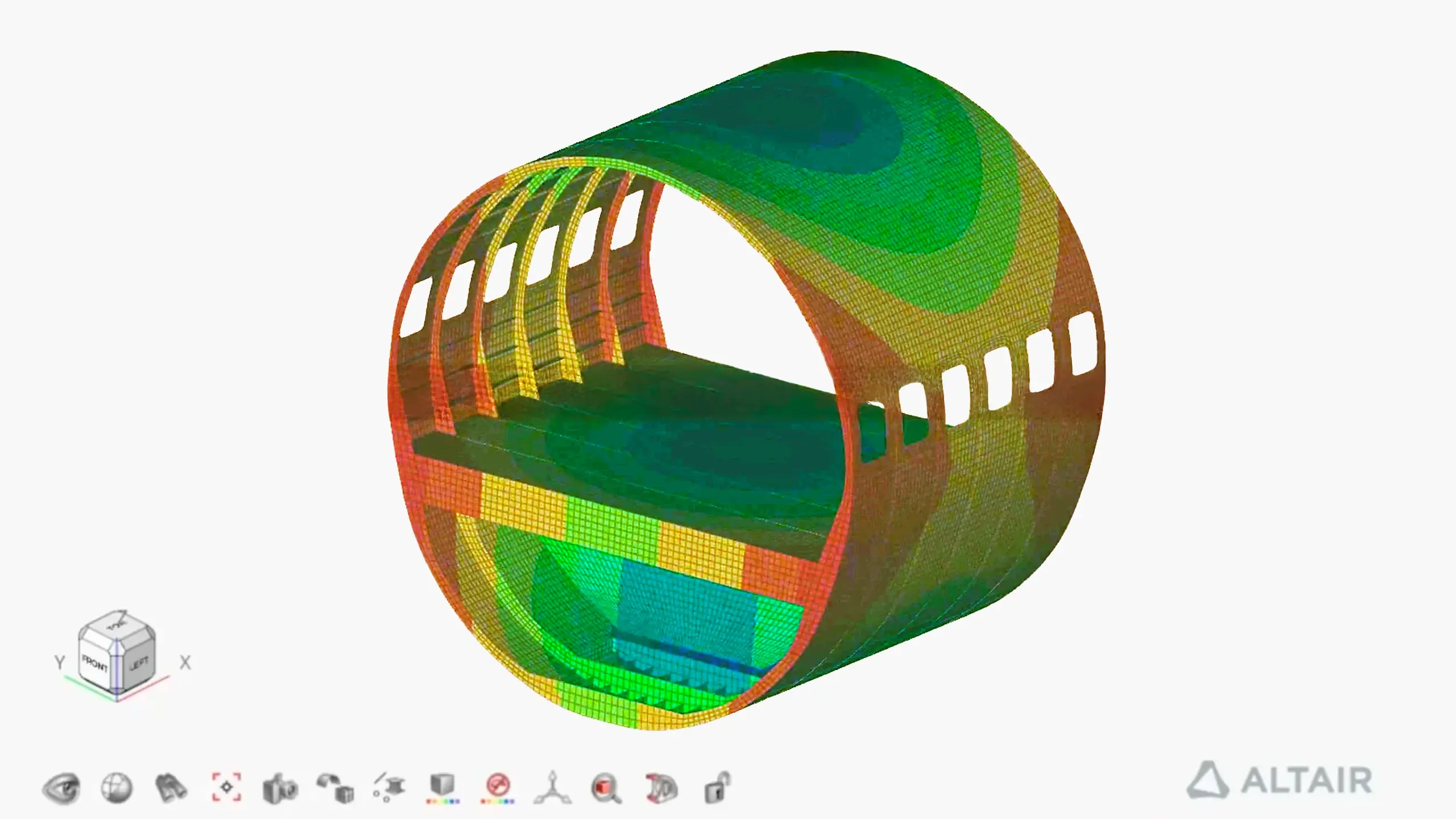

Supersonic Aeroelasticity for Aerospace Applications

OptiStruct provides advanced capabilities for aeroelastic analysis in high-speed environments, including the supersonic regime.

This functionality enables aerospace engineers to simulate aerodynamic force effects on aircraft structures exposed to supersonic airflow, assessing vibration resistance, structural divergence, and flutter behavior.

OptiStruct also supports the analysis of complex flight configurations, offering essential tools for designing high-performance aircraft.

Composites and Additive Manufacturing

OptiStruct delivers powerful tools for the design and optimization of composite materials, from skin shape definition to laminated layup configurations.

It also includes specific capabilities for 3D printing, with support for complex lattice structures, making it ideal for additive manufacturing applications.

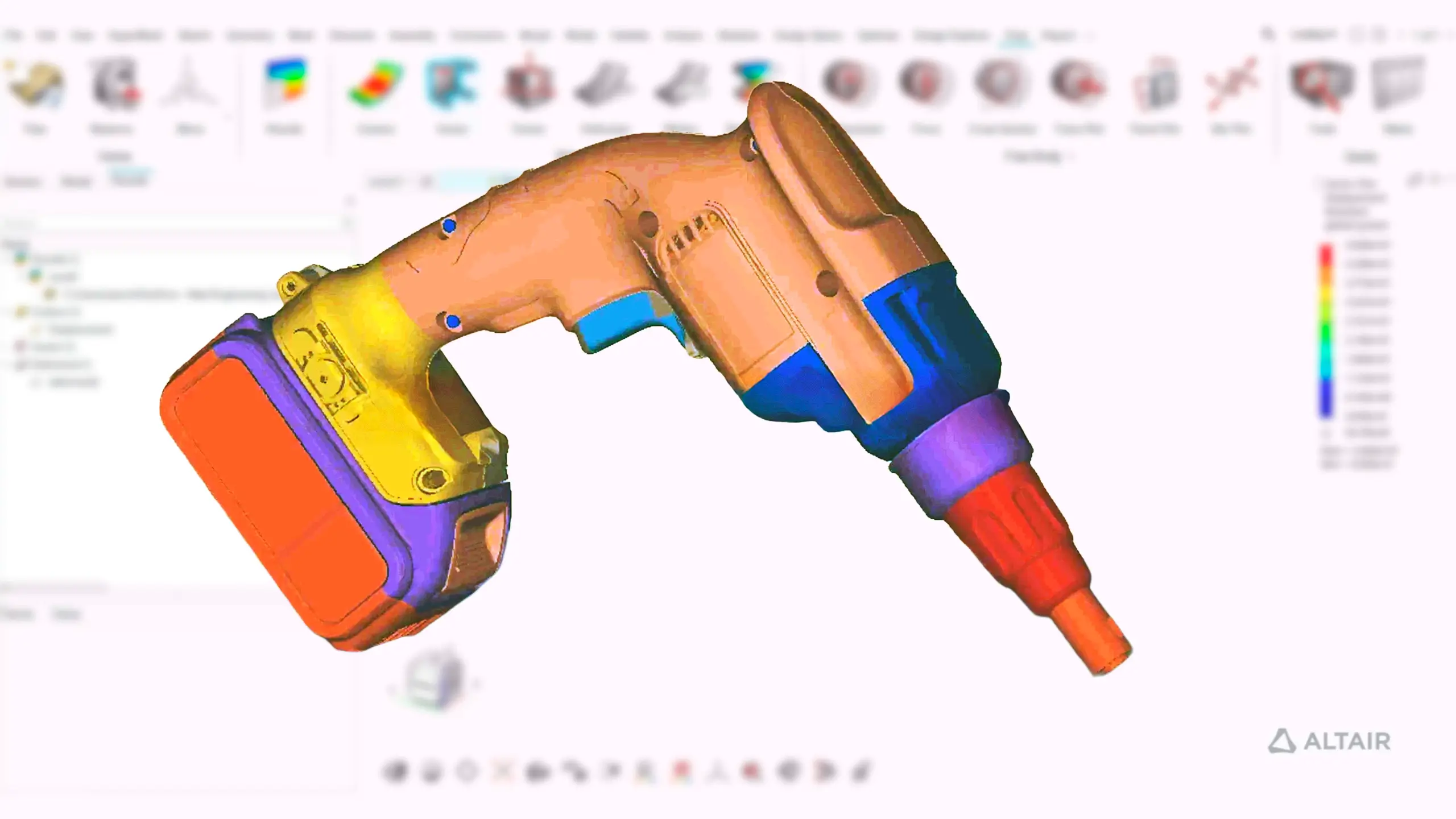

Material Design and Optimization: Toward Lightweight and Manufacturable Solutions

Material optimization is another core strength of OptiStruct.

From designing lightweight, high-strength components using advanced materials such as low-density foams, lattices, and composites, to managing multiple material configurations, OptiStruct offers a complete suite for component optimization.

With integration of the Altair® Material Data Center™, engineers can efficiently manage material data and enhance manufacturability by considering constraints such as erosion, failure, and durability.

Its compatibility with both additive manufacturing and traditional production methods makes OptiStruct a versatile solution across various production strategies.

Request the Optistruct trial now

Try OptiStruct and design in a smarter, lighter and more efficient way. The ideal choice to take your product engineering to the next level.